The complete spraywelder includes:

High Spray Rates - Specially designed nozzles achieve optimum performance

with all of our various powder groupings. Spray rates up to 19 lbs/hr (9 kg/hr) are

achieved with our standard model, and up to 35 lbs/hr (16 kg/hr) with our high-output

unit, the model J-3.

Tight Spray Patterns - The nozzles and focused air jets achieve the narrowest

spray pattern commercially available. More alloys is delivered to the part faster, with

less overspray, minimizing operator time and consumable investment.

Dense Coatings - Flame energy of up to 92,000 BTU’s and increased target

efficiency mean extremely hot spray particles are delivered to the base metal. The

final result is a strong, dense overlay.

Reliability- The Spraywelder pistol is designed and built for years of daily use.

O-rings are used throughout the unit and gas passages are drilled into a solid

aluminum body. The valve assembly is piston-activated for positive, leak-proof

control over all gases and maximum safety. The air-cooled pistol handles the hottest jobs.

Easy Operation - The Spraywelder includes a control panel which can be positioned

up to 10 feet away. All gas pressure and flow adjustments are located on the panel.

The panel also secures the quick-release detachable 20 lb (9 kg) production-size

hopper, which feeds the gun through a vibrator-less compressed air circuit (no

expensive inert gases necessary). The lightweight pistol is compact and operates in

any position.

Safety - Built-in dual flash-back arrestors prevent accidental ignition in oxygen and

fuel-gas supply hoses.

Versatility - Versatility - The Spraywelder applies a wide range of powdered alloys, including

Colmonoy Sprayweld powders (optimized for use with the Spraywelder), other

spray-and-fuse alloys and metallizing powders, such as SoloCoat™

powders

and CoiSpray™

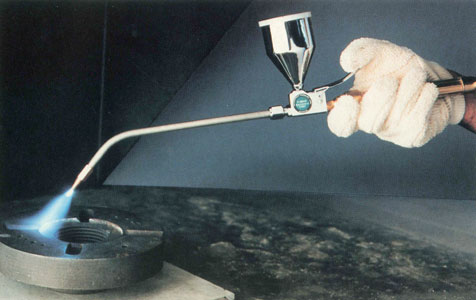

Wall Colmonoy's four Fusewelder models are the result of over 25 years of refinement in the engineered design of powder flame-spraying equipment. We offer the most extensive line of powder application touches available. The fusewelder system is a special oxyacetylene torch which preheats the base metal, sprays powdered alloy and fuses deposits to the workpiece.. all with one integrated unit.

The equipment group includes all the tools needed to complete the setup of a Spraywelder station (except air, oxygen and acetylene):